CNC Machining vs. Injection Molding

Leave a CommentThe manufacturing processes of computer numerical control (CNC) machining and injection molding differ in their methodology, capabilities, and advantages. The CNC machining process involves removing material to create a finished part, whereas injection molding relies on introducing liquefied materials into a hollow mold to shape and generate a product. Read on for a detailed examination of CNC plastic machining vs. injection molding and the benefits of these processes to gain valuable insights for your next plastic fabrication project.

What Is CNC Machining?

Unlike additive methods such as 3D printing, the CNC machining process is a subtractive manufacturing technique that uses dies and automated equipment to cut material away from a workpiece to achieve a part in the desired dimensions and shape. Once computer-aided design (CAD) software translates a part design into digital instructions, CNC machines rapidly and repeatably produce precise, uniform, cost-effective parts with minimal oversight by human workers. The process allows for design versatility and has the capability to create custom components from stock pieces. However, accuracy may suffer in large or bulky CNC-machined parts, and the process becomes less cost-effective for intricate designs.

What Are the Benefits of CNC Machining?

Depending on your application, CNC machining can be beneficial for:

- High-precision, low-defect production. CNC machining offers higher accuracy than traditional machining methods. The process reliably follows a product’s CAD designs, ensuring that parts are uniform and virtually defect-free to dependably match product specs. Automation also significantly decreases the chance of introducing human error.

- Expedited manufacturing and assembly. As a high-speed manufacturing technique, CNC machining is intrinsically efficient. Advanced CNC machines can even use automation to load billets into equipment and offload finished goods autonomously. As for assembly, even for complex designs, CNC machining produces consistent, accurate parts for optimal fit with coordinating components.

- Little or zero waste generation. This subtractive manufacturing process is precise in removing non-essential material, reducing waste. Also, given its accuracy, CNC machining minimizes part damage and the need to throw out or rework components.

What Is Injection Molding?

Among the most popular techniques for fabricating plastic components, plastic injection molding fills complex molds with molten material to create parts with intricate designs. The plastic melts and mixes with any additives in a heated barrel before the injection unit transfers the material into the cavity of a mold. A clamp holds the mold closed as the material cools, and the plastic ultimately cures in the shape of the mold’s cavity. Plastic injection molding creates precise components in various sizes ranging from small components to vehicle body panels, and it’s ideal for high-volume runs of a single product.

What Are the Benefits of Injection Molding?

Injection molding offers the following advantages when manufacturing a part:

- Improved strength for reliable durability. Depending upon the fillers you choose to add to your molding materials, injection molding can produce parts with improved strength for better durability.

- Uniformity and repeatability. Using molds for production allows for high uniformity in part manufacturing, generating repeatable parts from one production run to the next.

- Tight tolerances. This precision process creates parts with tight tolerances that adhere to product specifications.

- Capacity for high-volume manufacturing. Using injection molding lends efficiency to manufacturing operations, allowing you to generate high volumes of components within a short time frame for optimal productivity.

- Affordability. Fast, high-volume production equates to lower costs per part. Also, it’s possible to reuse the materials, making injection molding a cost-effective process.

- Material and design versatility. The injection molding process is compatible with an array of materials such as plastics and elastomers. That, and the fact that it can generate parts in a variety of sizes and shapes, makes this technique a flexible option for manufacturing.

- Pleasing aesthetics. Injection-molded parts require minimal finishing treatments after manufacturing, which has the added benefit of making such components visually pleasing.

Injection Molding Services From Dan-Kar

CNC machining and injection molding are two distinct manufacturing techniques that offer unique advantages depending on your project’s desired outcome. The choice between these techniques relies on various factors such as material, cost, and production volume. A thorough understanding of these processes can help your business make informed decisions and optimize manufacturing processes for maximum accuracy, efficiency, and productivity.

For over 40 years, Dan-Kar Corp. has specialized in plastic fabrication projects for components of all shapes and sizes, with versatile offerings for materials and finishes. We offer in-house plastic injection molding services with a focus on quality, reliability, flexibility, cost-effectiveness, and excellent customer service. Our engineers work closely with our scientific, biomedical, and laboratory clients to ensure full satisfaction. We’ll walk you through each step from design, tooling development, and prototyping through production and quality assurance to ensure the end product meets your expectations.

We offer a range of production and manufacturing services to provide you with comprehensive solutions, whether you need a single prototype or high-volume manufacturing of complex parts. Request a quote today to partner with Dan-Kar and begin your project.

Best Plastics for Machining

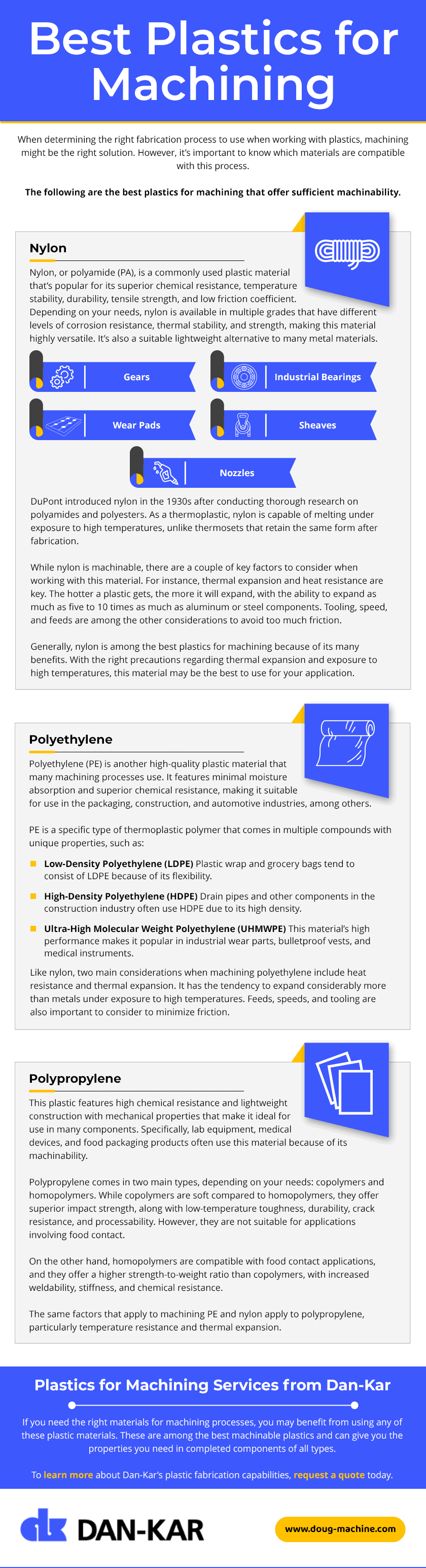

Leave a CommentWhen determining the right fabrication process to use when working with plastics, machining might be the right solution. However, it’s important to know which materials are compatible with this process.

The following are the best plastics for machining that offer sufficient machinability.

Nylon

Nylon, or polyamide (PA), is a commonly used plastic material that’s popular for its superior chemical resistance, temperature stability, durability, tensile strength, and low friction coefficient. Depending on your needs, nylon is available in multiple grades that have different levels of corrosion resistance, thermal stability, and strength, making this material highly versatile. It’s also a suitable lightweight alternative to many metal materials.

Its versatility, lightweight construction, and wear resistance make nylon among the best plastics for machining in the manufacture of components such as:

- Gears

- Industrial bearings

- Wear pads

- Sheaves

- Nozzles

DuPont introduced nylon in the 1930s after conducting thorough research on polyamides and polyesters. As a thermoplastic, nylon is capable of melting under exposure to high temperatures, unlike thermosets that retain the same form after fabrication.

While nylon is machinable, there are a couple of key factors to consider when working with this material. For instance, thermal expansion and heat resistance are key. The hotter a plastic gets, the more it will expand, with the ability to expand as much as five to 10 times as much as aluminum or steel components. Tooling, speed, and feeds are among the other considerations to avoid too much friction.

Generally, nylon is among the best plastics for machining because of its many benefits. With the right precautions regarding thermal expansion and exposure to high temperatures, this material may be the best to use for your application.

Polyethylene

Polyethylene (PE) is another high-quality plastic material that many machining processes use. It features minimal moisture absorption and superior chemical resistance, making it suitable for use in the packaging, construction, and automotive industries, among others.

PE is a specific type of thermoplastic polymer that comes in multiple compounds with unique properties, such as:

- Low-Density Polyethylene (LDPE) Plastic wrap and grocery bags tend to consist of LDPE because of its flexibility.

- High-Density Polyethylene (HDPE) Drain pipes and other components in the construction industry often use HDPE due to its high density.

- Ultra-High Molecular Weight Polyethylene (UHMWPE) This material’s high performance makes it popular in industrial wear parts, bulletproof vests, and medical instruments.

Like nylon, two main considerations when machining polyethylene include heat resistance and thermal expansion. It has the tendency to expand considerably more than metals under exposure to high temperatures. Feeds, speeds, and tooling are also important to consider to minimize friction.

Polypropylene

This plastic features high chemical resistance and lightweight construction with mechanical properties that make it ideal for use in many components. Specifically, lab equipment, medical devices, and food packaging products often use this material because of its machinability.

Polypropylene comes in two main types, depending on your needs: copolymers and homopolymers. While copolymers are soft compared to homopolymers, they offer superior impact strength, along with low-temperature toughness, durability, crack resistance, and processability. However, they are not suitable for applications involving food contact.

On the other hand, homopolymers are compatible with food contact applications, and they offer a higher strength-to-weight ratio than copolymers, with increased weldability, stiffness, and chemical resistance.

The same factors that apply to machining PE and nylon apply to polypropylene, particularly temperature resistance and thermal expansion.

Plastics for Machining Services from Dan-Kar

If you need the right materials for machining processes, you may benefit from using any of these plastic materials. These are among the best machinable plastics and can give you the properties you need in completed components of all types.

To learn more about Dan-Kar’s plastic fabrication capabilities, request a quote today.