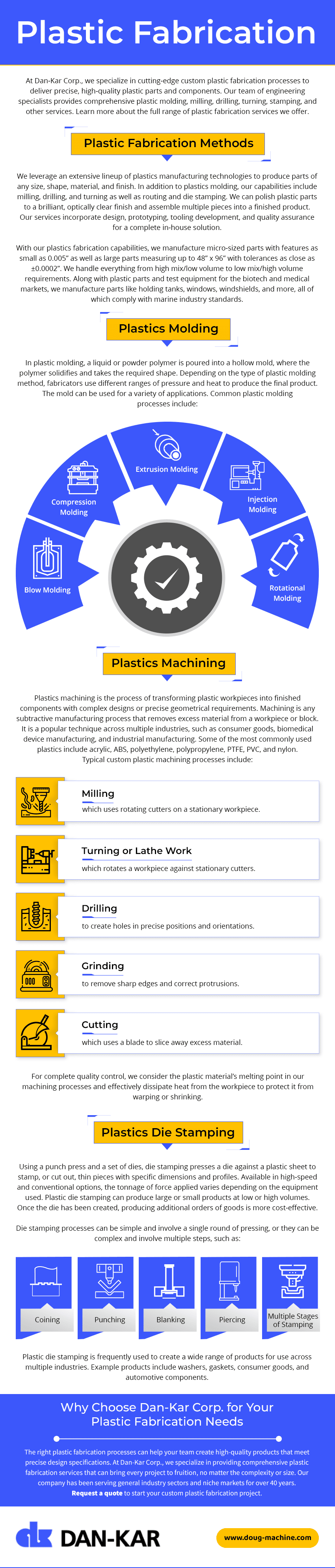

At Dan-Kar Corp., we specialize in cutting-edge custom plastic fabrication processes to deliver precise, high-quality plastic parts and components. Our team of engineering specialists provides comprehensive plastic molding, milling, drilling, turning, stamping, and other services. Learn more about the full range of plastic fabrication services we offer.

Plastic Fabrication Methods

We leverage an extensive lineup of plastics manufacturing technologies to produce parts of any size, shape, material, and finish. In addition to plastics molding, our capabilities include milling, drilling, and turning as well as routing and die stamping. We can polish plastic parts to a brilliant, optically clear finish and assemble multiple pieces into a finished product. Our services incorporate design, prototyping, tooling development, and quality assurance for a complete in-house solution.

With our plastics fabrication capabilities, we manufacture micro-sized parts with features as small as 0.005” as well as large parts measuring up to 48” x 96” with tolerances as close as ±0.0002”. We handle everything from high mix/low volume to low mix/high volume requirements. Along with plastic parts and test equipment for the biotech and medical markets, we manufacture parts like holding tanks, windows, windshields, and more, all of which comply with marine industry standards.

Plastics Molding

In plastic molding, a liquid or powder polymer is poured into a hollow mold, where the polymer solidifies and takes the required shape. Depending on the type of plastic molding method, fabricators use different ranges of pressure and heat to produce the final product. The mold can be used for a variety of applications. Common plastic molding processes include:

- Blow molding

- Compression molding

- Extrusion molding

- Injection molding

- Rotational molding

Plastics Machining

Plastics machining is the process of transforming plastic workpieces into finished components with complex designs or precise geometrical requirements. Machining is any subtractive manufacturing process that removes excess material from a workpiece or block. It is a popular technique across multiple industries, such as consumer goods, biomedical device manufacturing, and industrial manufacturing. Some of the most commonly used plastics include acrylic, ABS, polyethylene, polypropylene, PTFE, PVC, and nylon. Typical custom plastic machining processes include:

- Milling, which uses rotating cutters on a stationary workpiece

- Turning or lathe work, which rotates a workpiece against stationary cutters

- Drilling to create holes in precise positions and orientations

- Grinding to remove sharp edges and correct protrusions

- Cutting, which uses a blade to slice away excess material

For complete quality control, we consider the plastic material’s melting point in our machining processes and effectively dissipate heat from the workpiece to protect it from warping or shrinking.

Plastics Die Stamping

Using a punch press and a set of dies, die stamping presses a die against a plastic sheet to stamp, or cut out, thin pieces with specific dimensions and profiles. Available in high-speed and conventional options, the tonnage of force applied varies depending on the equipment used. Plastic die stamping can produce large or small products at low or high volumes. Once the die has been created, producing additional orders of goods is more cost-effective.

Die stamping processes can be simple and involve a single round of pressing, or they can be complex and involve multiple steps, such as:

- Coining

- Punching

- Blanking

- Piercing

- Multiple stages of stamping

Plastic die stamping is frequently used to create a wide range of products for use across multiple industries. Example products include washers, gaskets, consumer goods, and automotive components.

Why Choose Dan-Kar Corp. for Your Plastic Fabrication Needs

The right plastic fabrication processes can help your team create high-quality products that meet precise design specifications. At Dan-Kar Corp., we specialize in providing comprehensive plastic fabrication services that can bring every project to fruition, no matter the complexity or size. Our company has been serving general industry sectors and niche markets for over 40 years. Request a quote to start your custom plastic fabrication project.