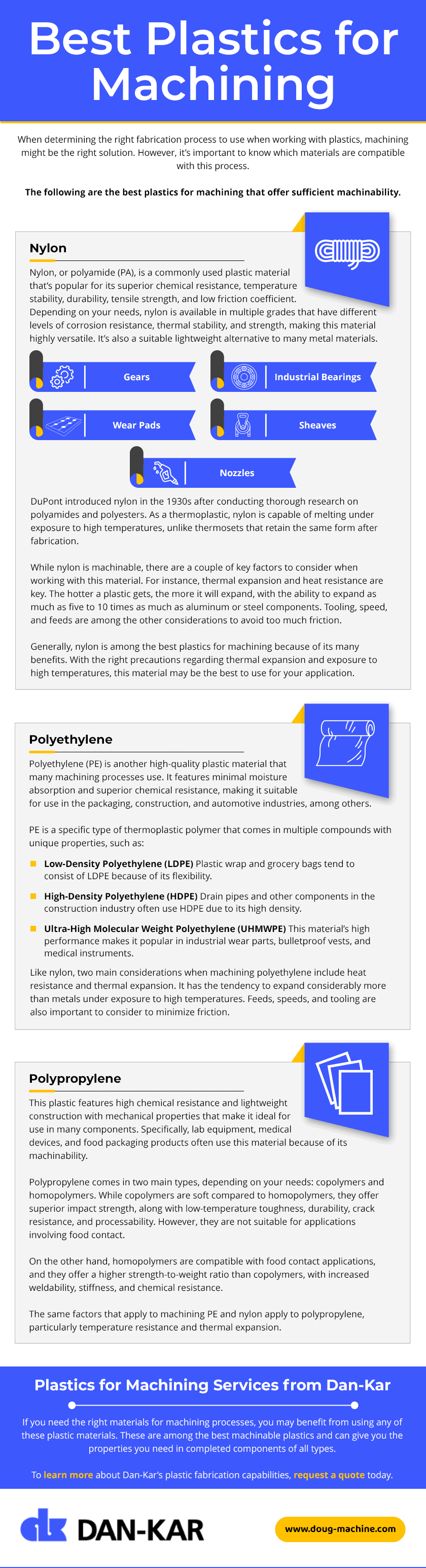

Best Plastics for Machining

When determining the right fabrication process to use when working with plastics, machining might be the right solution. However, it’s important to know which materials are compatible with this process.

The following are the best plastics for machining that offer sufficient machinability.

Nylon

Nylon, or polyamide (PA), is a commonly used plastic material that’s popular for its superior chemical resistance, temperature stability, durability, tensile strength, and low friction coefficient. Depending on your needs, nylon is available in multiple grades that have different levels of corrosion resistance, thermal stability, and strength, making this material highly versatile. It’s also a suitable lightweight alternative to many metal materials.

Its versatility, lightweight construction, and wear resistance make nylon among the best plastics for machining in the manufacture of components such as:

- Gears

- Industrial bearings

- Wear pads

- Sheaves

- Nozzles

DuPont introduced nylon in the 1930s after conducting thorough research on polyamides and polyesters. As a thermoplastic, nylon is capable of melting under exposure to high temperatures, unlike thermosets that retain the same form after fabrication.

While nylon is machinable, there are a couple of key factors to consider when working with this material. For instance, thermal expansion and heat resistance are key. The hotter a plastic gets, the more it will expand, with the ability to expand as much as five to 10 times as much as aluminum or steel components. Tooling, speed, and feeds are among the other considerations to avoid too much friction.

Generally, nylon is among the best plastics for machining because of its many benefits. With the right precautions regarding thermal expansion and exposure to high temperatures, this material may be the best to use for your application.

Polyethylene

Polyethylene (PE) is another high-quality plastic material that many machining processes use. It features minimal moisture absorption and superior chemical resistance, making it suitable for use in the packaging, construction, and automotive industries, among others.

PE is a specific type of thermoplastic polymer that comes in multiple compounds with unique properties, such as:

- Low-Density Polyethylene (LDPE) Plastic wrap and grocery bags tend to consist of LDPE because of its flexibility.

- High-Density Polyethylene (HDPE) Drain pipes and other components in the construction industry often use HDPE due to its high density.

- Ultra-High Molecular Weight Polyethylene (UHMWPE) This material’s high performance makes it popular in industrial wear parts, bulletproof vests, and medical instruments.

Like nylon, two main considerations when machining polyethylene include heat resistance and thermal expansion. It has the tendency to expand considerably more than metals under exposure to high temperatures. Feeds, speeds, and tooling are also important to consider to minimize friction.

Polypropylene

This plastic features high chemical resistance and lightweight construction with mechanical properties that make it ideal for use in many components. Specifically, lab equipment, medical devices, and food packaging products often use this material because of its machinability.

Polypropylene comes in two main types, depending on your needs: copolymers and homopolymers. While copolymers are soft compared to homopolymers, they offer superior impact strength, along with low-temperature toughness, durability, crack resistance, and processability. However, they are not suitable for applications involving food contact.

On the other hand, homopolymers are compatible with food contact applications, and they offer a higher strength-to-weight ratio than copolymers, with increased weldability, stiffness, and chemical resistance.

The same factors that apply to machining PE and nylon apply to polypropylene, particularly temperature resistance and thermal expansion.

Plastics for Machining Services from Dan-Kar

If you need the right materials for machining processes, you may benefit from using any of these plastic materials. These are among the best machinable plastics and can give you the properties you need in completed components of all types.

To learn more about Dan-Kar’s plastic fabrication capabilities, request a quote today.